AI is making notable advancements across various fields, from boosting workplace productivity to aiding in early cancer detection. But could AI eventually enable the printing of human organs? While this idea may seem distant, recent research at Washington State University suggests it could become a reality. Researchers have developed a technique using AI, specifically Bayesian Optimization, that enhances the speed and efficiency of 3D printing lifelike human organs. This study, published in the journal Advanced Materials Technologies, indicates that this AI method could facilitate the 3D printing of complex designs, ranging from artificial organs to electronic components and wearable biosensors. The breakthrough here is that this AI algorithm could enable the creation of even the most intricate structures.

According to the WSU Insider, the algorithm was trained to identify and print the best versions of kidney and prostate organ models, producing 60 progressively improved versions of these organs. Kaiyan Qiu, a co-author and assistant professor at the WSU School of Mechanical and Materials Engineering, noted that this approach could optimize results, saving time, cost, and labor. Despite the growth in 3D printing technology, engineers still face challenges in setting up their projects due to the complexity of choosing materials, printer configurations, and nozzle dispensing pressures. Jana Doppa, another co-author and associate professor of computer science at WSU, highlighted the overwhelming number of combinations and the associated costs of trial and error.

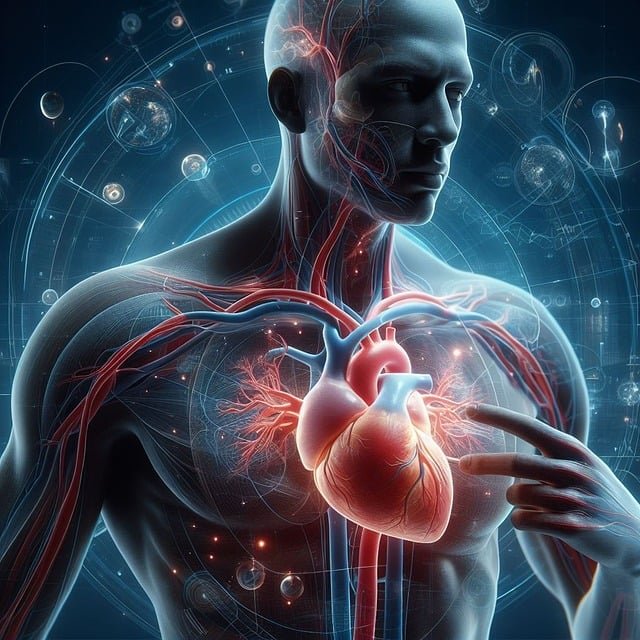

The AI algorithm creates organ models by balancing geometric precision, density, and printing time to produce realistic and functional prototypes. This technique reduces the time and materials required to find optimal 3D printing settings for complex objects. If further developed, this technology could have applications beyond medicine, extending to fields such as computer science, aviation, and automotive industries. The 3D-printed human models could be used for training surgeons or testing implant devices, provided they accurately replicate the mechanical and physical properties of real organs, including veins, arteries, and channels.